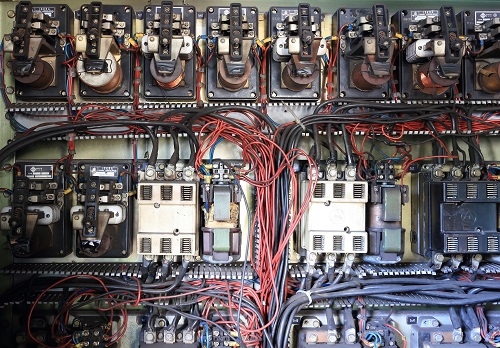

OSHA regulation requires employers keep electrical equipment well maintained, from organizing wiring to tightening screws. NFPA 70E standards have similar requirements. The goal is to prevent electrical accidents from equipment failure. T/C Risk Management NFPA 70E electrical safety training covers the importance of equipment maintenance for reducing accidents and avoiding OSHA citations.

Broken equipment, frayed wires, and failed circuit breakers can all lead to deadly electrical accidents. And electrical problems put the facility at risk for fire, another incentive for regular maintenance.

It is better to delay work for one hour to perform maintenance than be shut down for weeks due to total equipment failure. T/C Risk Management will help you create a maintenance schedule for your electrical equipment. Some equipment may require daily or weekly checks. Other pieces may only need annual maintenance. Sticking to a schedule will make noticing problems easier on your workers.

Even minor safety checks can prevent large-scale accidents. If employees know what to look for they can protect themselves and the equipment from harm. T/C Risk training shows qualified and unqualified workers how to spot potential problems before they become a risk.

Electrical Lockout/Tagout

Electrical Lockout/TagoutBefore working on any electrical equipment, it is important to use proper electrical lockout/tagout procedures. LOTO training allows workers to safely shutoff power sources to perform maintenance. T/C Risk training covers 1910.47 OSHA LOTO and 1910.331 OSHA LOTO safety classes.

Don’t forget about personal protective equipment (PPE) for your workers. Be sure all your employees wear the correct safety glasses, insulated gloves, and flame-resistant clothing when working around electrical equipment.

Regular equipment maintenance means less downtime. If equipment breaks down and has to be replaced, you’re losing valuable worktime. Scheduled maintenance lowers the chances of expensive replacements.

Electrical equipment safety training also reduces the possibility of expensive OSHA citations. T/C Risk will build a safety policy based on your company’s current equipment. The policy will make it clear how employees are to stay safe and follow NFPA 70E standards.